Swine industry efforts to improve biosecurity have been focused on breeding herds, with little attention given to the wean-to-market phase of production. It has been estimated that 55% of growing-pig groups that are negative for porcine reproductive and respiratory disease virus (PRRSV) at placement are positive at marketing, suggesting that PRRSV was introduced sometime during the growing period causing economic losses of approximately $2.29/pig placed due to higher mortality and slower growth.1 Although information on how frequently groups of growing pigs are infected with porcine epidemic diarrhea virus (PEDV) is not available in the literature, the lateral introduction of the virus in growing pigs adversely affects average daily gain (ADG), average daily feed intake, and reduces growth.2 In one swine production system, the introduction of PEDV during late finishing reportedly reduced ADG by 21.4%.3 Additionally, when growing pigs become infected, they serve as a source of the virus that may increase the incidence of outbreaks in swine breeding herds, where economic consequences can be much larger. Data from the Swine Disease Reporting System demonstrates that significantly increased detection of PRRSV in breeding herds is typically preceded by increased detection in growing pigs, supporting the hypothesis that the growing pig population is a major source of virus in the swine industry.4,5

One risk event that has the potential to introduce virus into growing pigs is transport to market. In the United States, groups of pigs are typically transported to market over several weeks, creating the opportunity for pigs remaining at the farm to become infected after the first loads are taken from the barn. The pigs remaining in the group are then subject to production losses and become a potential source of virus for other swine farms. It has been demonstrated that livestock trailers can serve as a source of transmission for PRRSV, PEDV,6,7 and other swine pathogens.

For pigs remaining on feed to become infected during a marketing event, a series of failures is required. First, the livestock trailer, driver, truck, or other pathogen carrying agent associated with the marketing event is contaminated with live infectious virus. Swine harvest plants receive animals from many sources daily, so PRRSV, PEDV, and other swine pathogens are likely present in the unloading area. It has been demonstrated that the livestock trailers used to haul pigs to market are frequently contaminated with virus.7 The driver, as well as the cab of the truck, may also serve as potential pathogen carrying agents for the viruses. Second, there is a failure to mitigate that contamination. Third, the virus is transferred as the pigs being marketed are loaded from the contaminated carrying agent to the remaining pigs in the group.

Currently, there is much variation in how livestock trailers are handled between transporting loads of market pigs to harvesting plants in the United States. In many cases, the trailers are not washed, disinfected, or dried between loads of market pigs due to the lack of trailers, truck washes, and other swine transport-related infrastructure. Even if livestock trailers were washed, disinfected, and dried, contamination may still occur if these procedures are not done correctly or standard operating procedures are not implemented. If livestock trailers or other pathogen carrying agents associated with the marketing event are not washed, disinfected, and dried, or done so poorly, between loads, it is unlikely that the contamination will be mitigated. Therefore, when the livestock trailers, trucks, and drivers return from a swine harvest plant and enter growing pig sites to load market pigs, contamination with live infectious PRRSV, PEDV, or other swine pathogens may occur. Viral transfer from the contaminated livestock trailer, driver, or other pathogen carrying agents to the pigs must occur during the loadout procedure for pigs remaining in the barn to become infected. Little research has been done to assess how frequently this failure occurs or to evaluate alternative biosecurity measures to reduce the frequency.

In a previous study conducted by the investigators, a fluorescent powder was used to evaluate if the addition of a bench entry system in a commercial swine facility with a shower reduced the likelihood of personnel introducing environmental contamination into a swine farm.8 Glo Germ powders and lotions have also been effectively used in the human medical field to represent human fluid and environmental bacteria contamination transfer in doffing of personal protective equipment, washing of hands, and glove removal methods.9-12

The objective of this study was to evaluate the effectiveness of a staged vs conventional loading procedure of market pigs for reducing the transfer of contaminants from livestock trailers to the barn using fluorescent powder.

Animal care and use

All study procedures were performed in accordance with the swine production and welfare policy of the production system.

Materials and methods

Preliminary data collection

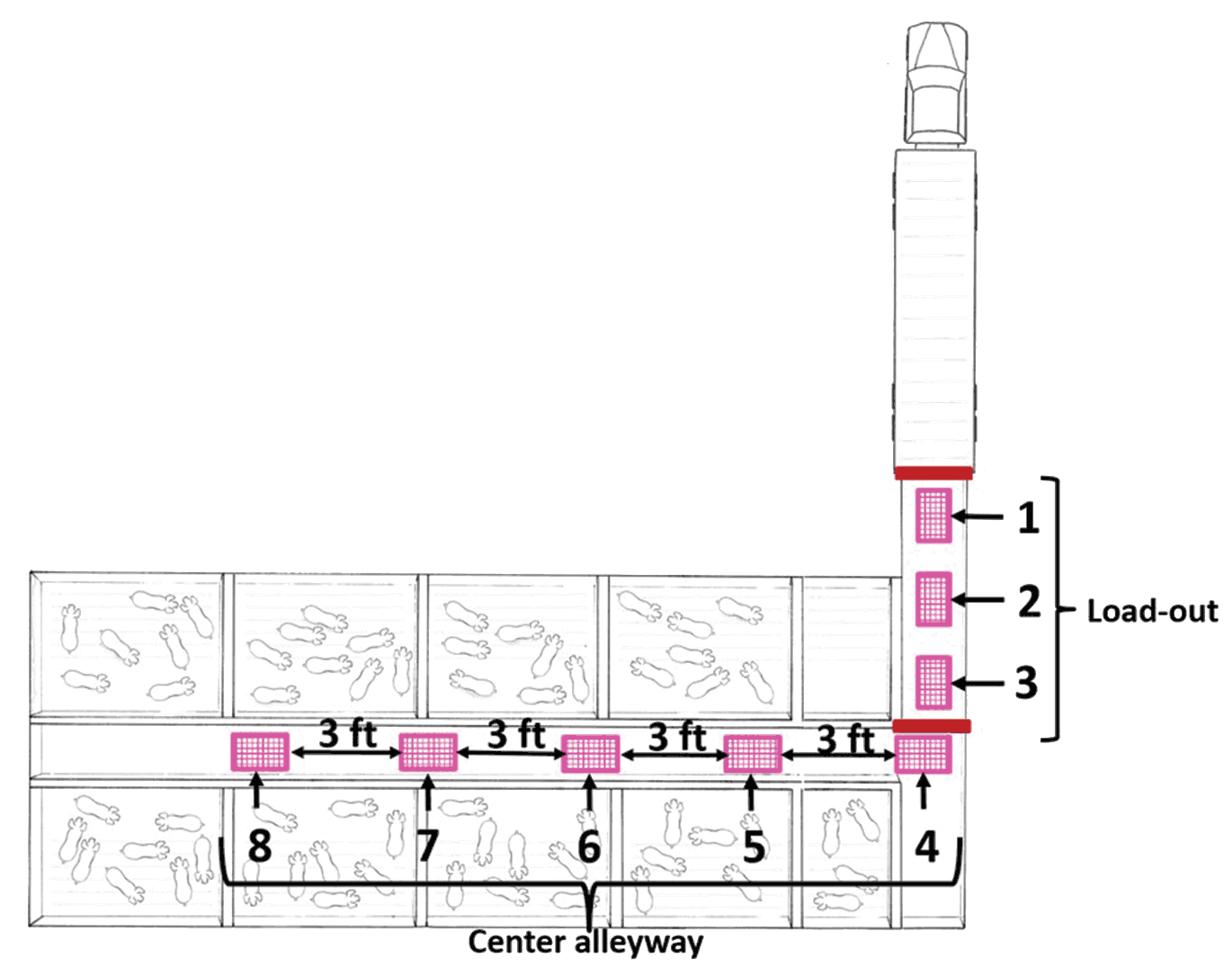

A pilot study was conducted to see if fluorescent powder could be successfully used to visualize and measure the transfer of environmental contamination from livestock trailer to the barn. Fluorescent powder (216 g) was mixed with 0.5 L of obstetrical (OB) lubricant (Huvepharma, Inc) and 0.25 kg of wood shavings in a large, sealable plastic bag. This mixture was spread evenly on a portion of the livestock trailer floor just inside the roll-up door that opens to the chute. After pig loadout, an ultraviolet light was used to scan the loadout chute, loadout alleyway, center alleyway of the barn, and pens in the barn. Fluorescent powder could be found in the loadout chute, loadout alleyway, center alleyway in the barn, and in the first three pens adjacent to the center alleyway.

Study facility design

The study was conducted at 20 growing pig sites that were owned by a single production system. The study was conducted in July and August 2019. Each of the 20 sites consisted of two attached barns and approximately 1200 pig spaces/barn. Inclusion criteria for the site layout included a loadout chute that was enclosed, immobile, and approximately 4 m long and a center alleyway in the barn at least 7.62 m long that the loadout crew would walk after exiting the loadout area. Seventeen sites had a single loadout chute located in one of the barns, adjacent to a centrally located office. There was one loadout alleyway that led to the center alleyway in the barn and was enclosed on one side by a wall and a 3 ft high solid cement wall on the other side. The loadout alleyway was adjacent to an empty small holding pen. One replicate in the conventional group had a single loadout chute at one end of both attached barns. Two sites, one in the staged and one in the conventional group, had a loadout chute directly connected to a wide central hallway between both barns. The central hallway was enclosed by walls, and no holding pen was present. A standard double deck livestock trailer can hold approximately 170 market swine, therefore loads were excluded if less than 165 pigs were loaded on a single trailer. Replicates were also excluded if personnel stepped completely over the established lines of separation more than twice.

Study design and treatment groups

A conventional (control) and staged loadout protocol were compared in this controlled study. Each group had 10 replicates. A replicate was defined as the last of the scheduled loads for that site in a single day. The final load of the day was chosen to avoid delaying subsequent loads and disrupting market schedules while the measurements were taken. Each growing pig site was used for a single replicate to prevent the possibility of residual contamination from a previous replicate.

The initial allocation of treatment groups was done by blocking on day of the week (Sunday through Friday) and then randomizing replicates within each day of the week. Blocking on the day of the week was done to control for any potential differences in procedures by the day of the week or if employees were more or less rushed to complete the loading procedure on certain days of the week. Randomization was done using the rand function in Excel (2016, Microsoft Corporation). However, the final allocation (Table 1) was altered, and therefore no longer random, because of last-minute changes in the loadout schedule and several replicates were discarded when violations of at least one of the inclusion or exclusion criteria occurred.

| Day of the Week | Conventional | Staged |

|---|---|---|

| Sunday | 1 | 2 |

| Monday | 0 | 1 |

| Tuesday | 3 | 2 |

| Wednesday | 3 | 3 |

| Thursday | 2 | 1 |

| Friday | 1 | 1 |

| Total | 10 | 10 |

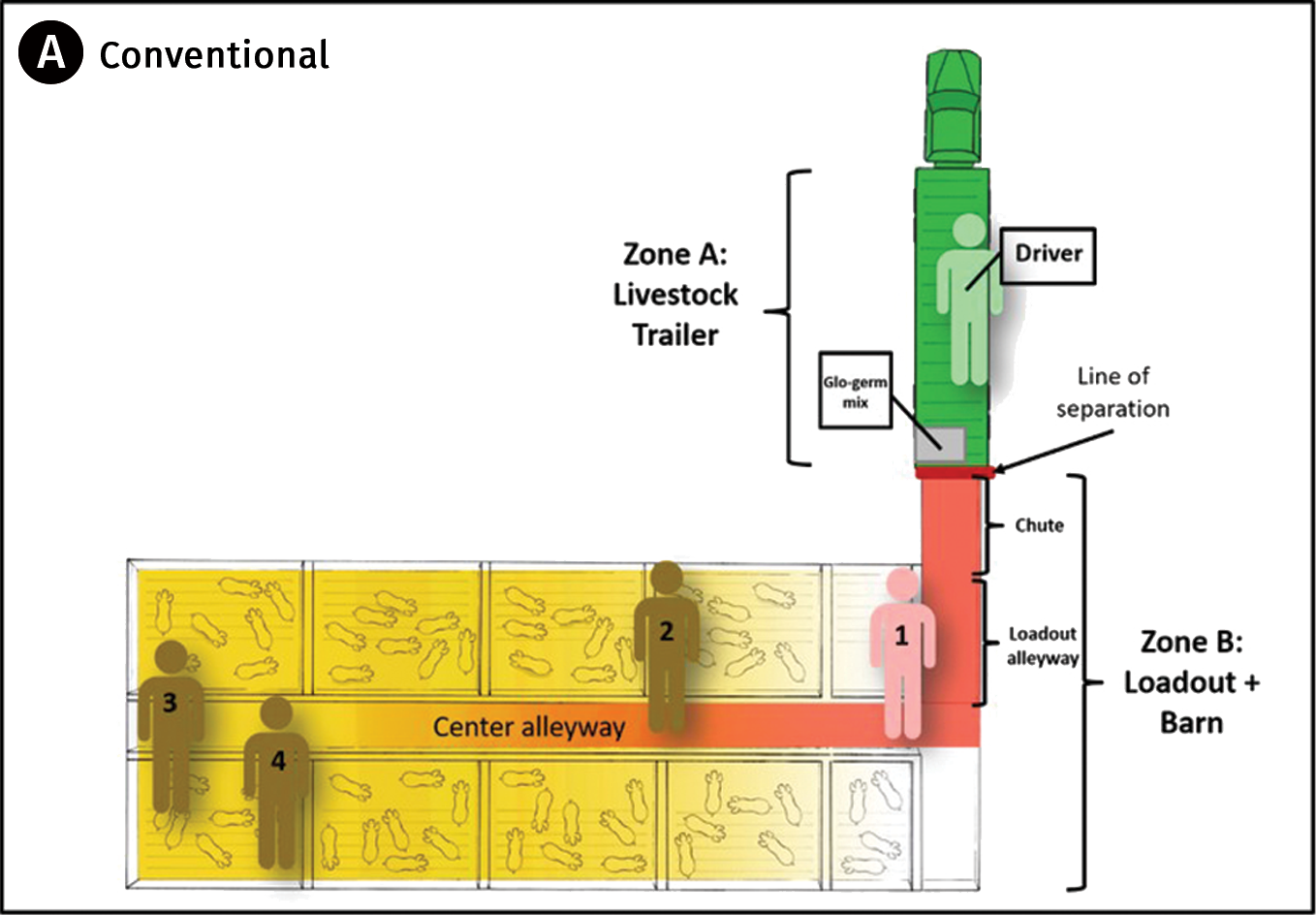

For the conventional group, a crew of 3 to 4 people loaded the pigs according to the production system’s conventional loading protocol (Figure 1A). Any member of the crew (Person 1) moved pigs from the center alleyway of the barn, through the loadout alleyway, and up the chute. Person 1 was not allowed to cross the line of separation between the livestock trailer and the loadout chute. The driver was confined to the trailer or Zone A and was not allowed to cross the line of separation between the chute and the back of the livestock trailer. The remaining members of the loading crew were restricted to Zone B and moved the pigs to be loaded from the pens down the center alleyway until they were transferred to Person 1. The barn, loadout alleyway, and chute were all part of the same zone (Zone B), and any member of the loadout crew could move freely within the zone.

For the staged group, there were two lines of separation (Figure 1B). The first line of separation was between the livestock trailer (Zone A) and the loadout chute in the loadout area (Zone B). The driver had to remain in the trailer. A single member of the loadout crew (Person 1) was designated to the loadout, or Zone B. The second line of separation was approximately between the loadout alleyway (Zone B) and the remainder of the barn (Zone C). Person 1 stayed in Zone B and the other members of the loadout crew (Persons 2 and 3) stayed in the barn, or Zone C. Person 1 was able to step into the buffer zone, which was considered part of the loadout (Zone B), to let pigs pass.

The same loadout crew, made up of 4 members, loaded 18 of the 20 replicates. They completed all 10 of the staged replicates and 8 of the 10 conventional replicates. Two other loadout crews loaded the 2 conventional replicates to accommodate loadout schedules. These two loadout crews had 3 members per crew. On day 1 of the study, the study investigators conducted a session to train the loadout crews how to perform the staged loading procedure. Two diagrams with instructions in English and Spanish on how to perform the staged and conventional loadout procedures were given to the loadout crews and loadout crew managers and explained in detail. Before each loadout, the loadout crews were told which procedure they needed to perform and reminded of the directions for that procedure.

Fluorescent powder

A fluorescent powder (Glo Germ; Glo Germ Company) was used to visualize contamination from the livestock trailer to the barn. The fluorescent powder simulated the behavior of pathogens from fomites and is similar in size to bacteria, approximately 1 to 5 microns or less.8 The powder appears white under natural light and fluoresces when exposed to ultraviolet light.

Outcome variables

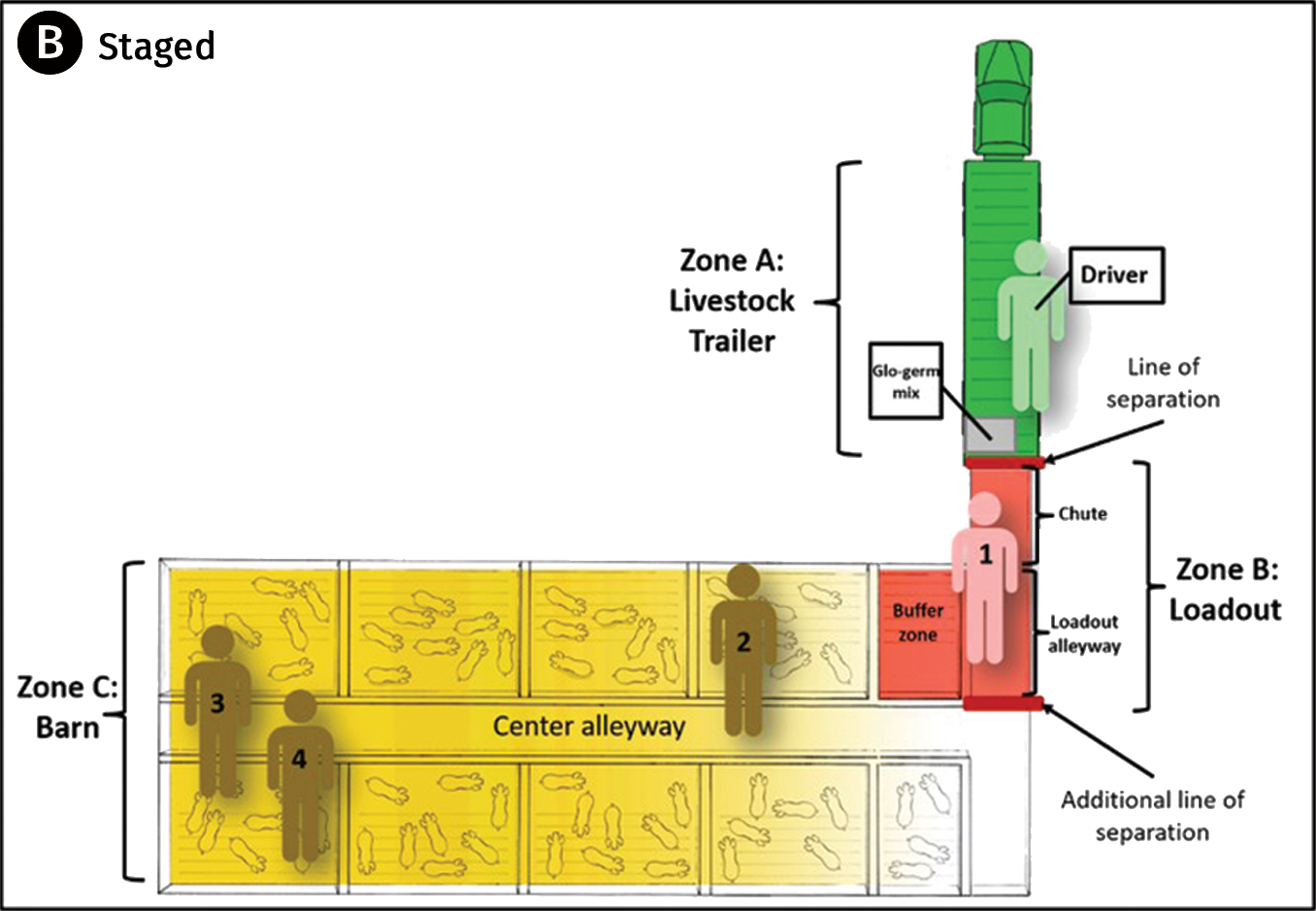

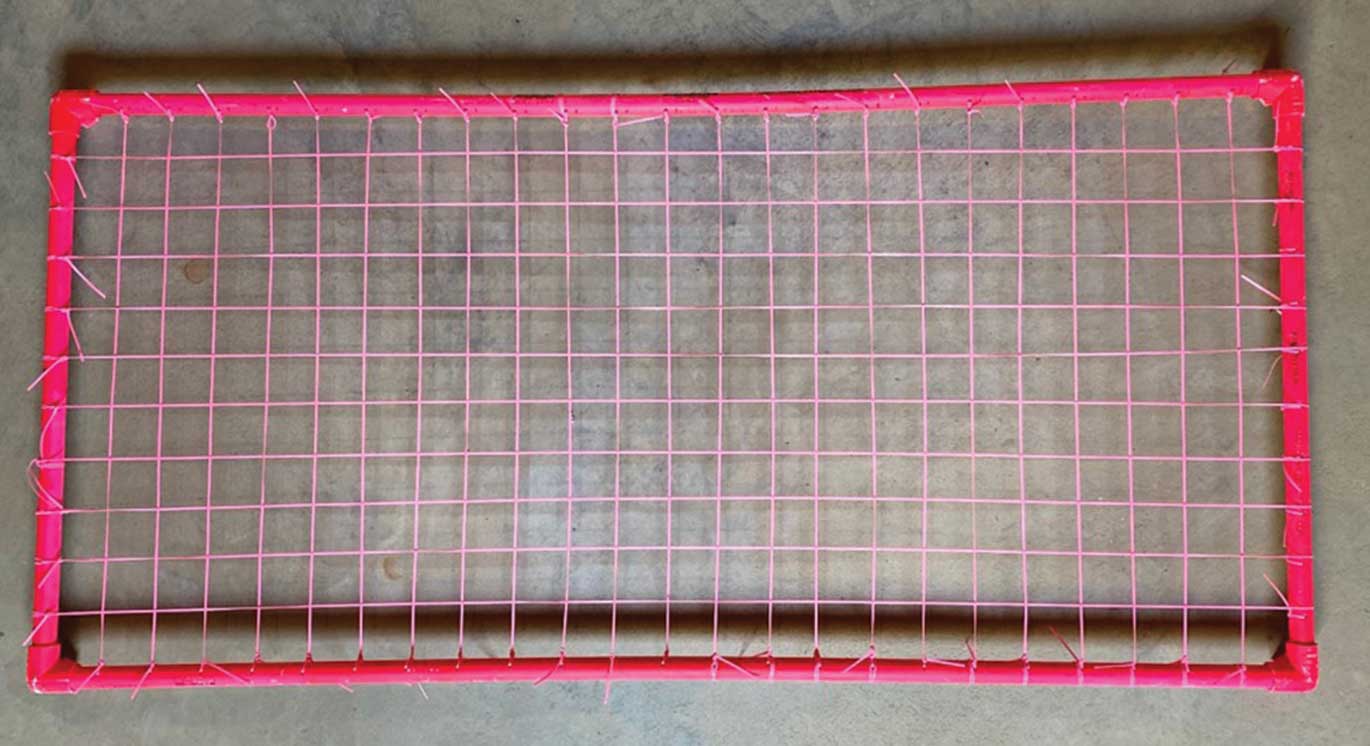

A single grid was constructed to measure the level of contamination (Figure 2). The grid was 120 × 55 cm2 and divided into 264 squares, each measuring 5 × 5 cm. The grid was made of polyvinyl chloride (PVC) pipe and flat fluorescent plastic string (Rexlace plastic craft lacing; Pepperell Braiding Company) placed at 5 cm intervals in the PVC pipe grid. The grid was coated with a fluorescent paint that was visible under long-wave ultraviolet light (UV-A), but a different fluorescent color than that of the fluorescent powder. Measurement of contamination was taken using the grid at 8 different locations shown in Figure 3. The measurement locations included: 1 ft in front of the end of the loadout chute adjacent to the trailer; 1 ft in front of the beginning of the loadout chute; 1 ft behind the second line of separation within the loadout area; directly in front of the line of separation in the center alleyway; and 4 locations in the center alleyway spaced 3 ft apart from the previous measurement. Measurements for each location were recorded by counting the number of 5 × 5 cm squares with any amount of fluorescent powder present.

Also recorded were major, minor, and necessary violations of the protocols, and number of loadout crew members present for the procedure. A minor violation was defined as a loadout tool crossing the line of separation or a person partially crossing a line of separation, such as half a boot. A major violation was defined as a person walking completely across a line of separation. A necessary violation occurred when an animal required assistance on the loadout chute, trailer, or between the loadout chute and trailer. The necessary violations occurred when a member of the loadout crew or the driver stepped completely over the line of separation to help the animal.

Study procedures

Immediately before each scheduled site visit, 216 g of fluorescent powder was mixed with approximately 0.5 L of OB gel and 0.25 kg of wood shavings in a large, sealable plastic bag. Before pigs were loaded on the last scheduled load for the evening, the fluorescent powder mixture was spread evenly on a portion of the livestock trailer floor just inside the roll-up door that opens to the chute (Figure 4). When the staged protocol was followed, the location of the second line of separation was determined based on the design of the barn and marked with commercially available red livestock spray paint (Quik shot spray paint, LA-CO Industries). On the nights where the conventional protocol was followed, the location of the second line of separation was determined prior to loadout for the purpose of determining measurement locations, but not marked to avoid confusion with the loadout crew as to what protocol they needed to follow. The second line of separation was typically at the end of the loadout alley in the barn. In 3 instances, the barn’s loadout alleyway was a central hallway with no buffer zone. In these cases, the second line of separation was at the end of the central hallway, where the barn and hallway met. If there was not an appropriate buffer zone for Person 1 of the loadout crew during a staged loading replicate, the second line of separation was extended approximately two feet past the loadout area so Person 1 could establish an appropriate buffer zone to move out of the travel pathway of pigs being loaded into the chute. After the fluorescent powder mixture was spread evenly on the back of the livestock trailer, and the second line of separation was determined, the loadout procedure was observed. Violations were recorded and deemed as minor, major, or necessary violations. After the loadout was complete, Person 1 put on plastic boots by elevating their feet while standing in the loadout area and then stepping back into the barn. They were to avoid stepping on the floor of the loadout area once the plastic boots were on and return to the office to avoid cross-contamination after crossing the second line of separation. When the loadout crew exited the barn, the measurement grid was used to measure the contamination level at each of the locations shown in Figure 3. The lights were turned off and a UV-A flashlight (Lights of America) was used to illuminate any fluorescent powder present in the grid coordinates. If there was any powder inside the cell of the grid, it was counted as contaminated. This was repeated for each location. A primary investigator and 1 of the 6 secondary investigators were present to observe the loadout and to take measurements for all but 2 replicates. For these 2 replicates, 2 secondary investigators were present to observe the loadout and take measurements. Both investigators present would count the number of contaminated squares, and after counting, the secondary investigator would record the number of contaminated squares. An effort was made to take measurements in the evening, after sundown, or in the mornings before sunrise to visualize the fluorescent powder more easily.

Statistical analysis

All data was analyzed using PROC GLIMMIX (SAS version 9.4). A generalized linear mixed effects model with the Poisson response distribution and log link was used to model the number of contaminated cells as the response variable. Fixed effects included treatment (conventional or staged), sampling point (chute, in front of the chute, second line of separation, or center alley in barn 1-5), major violations (0 or 1), loading crew size (3 or 4), and minor violations (analyzed as a continuous variable). Interaction terms for treatment and sampling point, major violations and sampling point, and minor violations and sampling point were also included. The barn was analyzed as a random effect to account for repeated grid measurements at a single point in time for each load. Sampling points were treated as categorical variables. Only 1 of 20 replicates had 2 major violations, all others had either 0 or 1. Therefore, major violations were analyzed as a binary variable (0 for no major violations or 1 for one or more major violations). A pairwise comparison was performed on differences between the treatment groups at each sampling points, and differences in sampling point and major violations. A P value < .05 was considered significant.

Results

Three replicates were discarded and repeated. One because the number of animals loaded onto the truck was less than 165, one because there were over 2 major violations from the staged loading protocol, and one because the measurement grid did not fit in the loadout alleyway and an accurate measurement could not be obtained. At least 1 major violation occurred in 7 of the 20 replicates. Five of these replicates were the staged group, and 2 replicates were the conventional group. There were 0 necessary violations observed throughout the study. At least 1 minor violation occurred in 6 of the 20 replicates, 5 of which were the staged group and 1 was the conventional group. Data was successfully captured for 10 replicates for both treatments.

A summary of main fixed effects used in the model is displayed in Table 2. Treatment and sampling point were both statistically significant in the model (P = .01 and P < .001, respectively). Major violations and minor violations were not statistically significant (P = .14 and P = .16, respectively). The number of crew members was also not statistically significant (P = .31). When there were 4 crew members present during the conventional loadout procedure, the member that ran pigs up the loadout chute usually walked back into the barn at least 7.62 m in the center alleyway until the next group of pigs was brought to them. When there were 3 crew members, the member that ran the pigs up the loadout chute also walked back into the barn at least 7.62 m into the center alleyway. The only observable difference between the 3-member loadout crew and the 4-member loadout crew was that the member in the 3-member loadout crew moving the pigs up the loadout chute sometimes traveled further than the 7.62 m back into the center alleyway to receive the next group of pigs. Both crew sizes (3 vs 4) covered the same area that was measured in the center alleyway.

| Effect | Level | Estimate (SE) | P value* |

|---|---|---|---|

| Intercept | 3.67 (0.46) | < .001 | |

| Treatment | Conventional | -0.25 (0.50) | .01 |

| Staged | 0 | ||

| Sampling point | Center alley 1 | -1.26 (0.44) | < .001 |

| Center alley 2 | -2.31 (0.54) | ||

| Center alley 3 | -2.59 (0.62) | ||

| Center alley 4 | -3.30 (1.04) | ||

| Center alley 5 | -4.48 (1.75) | ||

| Chute | 1.89 (0.45) | ||

| In front of chute | 1.24 (0.32) | ||

| Second line of separation | 0 | ||

| Major violations (Binary) | 0 (no violations) | 0.33 (0.55) | .14 |

| 1 (more than 1 violation) | 0 | ||

| Crew size | 3 | 0.05 (0.04) | .31 |

| 4 | 0 | ||

| Minor violations | Continuous variable | 0.21 (0.15) | .16 |

The interaction between treatment and sampling points was statistically significant (P = .04) however, the interaction between major violations and sampling point and minor violations and sampling point were not statistically significant (P = .20 and P = .07, respectively). A comparison of the number of contaminated cells between each treatment group at each location is shown in Figure 5. The number of contaminated squares at center alleyway locations 1, 2, 3, and 4 were significantly lower for the staged group compared to the conventional group (P = .02, P = .007, P = .005, and P = .009, respectively). While the number of contaminated squares at center alleyway location 5 was lower for the staged group than the conventional group, the difference was not statistically significant (P = .057). The contamination at all other locations, the chute, in front of the chute, and the second line of separation, were not statistically significant (P = .24, P = .73, and P = .63, respectively) between the conventional and staged groups. It was not expected that measurements in the chute and loadout alleyway would be statistically significant from each other. The staged loading procedure should not affect how much contamination is conveyed from the trailer to the chute and loadout alleyway. The standard errors in the center alleyway for the conventional group were greater than those for the staged group (Figure 5).

The measurements taken in the loadout chute had consistently high levels of contamination, with at least 75% of the grid squares contaminated. Least squares means of contaminated cells for no major violations and 1 or more major violations across all treatment replicates were 15.75 and 22.96, respectively. At each sampling point, differences between replicates that had no major violations or 1 or more major violations, were not significant (P > .05) except for the center alleyway location 4 (P = .01).

Discussion

The staged loading procedure significantly reduced the amount of contamination, as simulated with fluorescent powder, from the back of the trailer to the barn alleyway at all center alleyway locations except for location 5, which was nearly significant. This could be due to center alley location 5 being the furthest measurement away from the trailer and distance could be a factor in contamination levels. In contrast, there were no significant differences between sampling points and major violations at any center alleyway location except for location 4. A possible explanation could be that contamination fell off a boot or loadout tool at this spot when moving through the barn. There is a large amount of variation in the conventional loading procedures in comparison to the staged loading procedure, suggesting that the amount of contamination that is conveyed from a livestock trailer to the barn is inconsistent and likely depends on several factors, including how frequently the line of separation between the trailer and chute is violated or the conventional loading procedure itself.

In both groups, the locations in the loadout chute consistently had a high level of contamination. This demonstrates that the load crew member(s) that are walking on the chute, most likely were picking up contamination on their boots, sorting panels, and other pig handling tools. The contamination level on the chute is not only due to violations of the line of separation from personnel, but also from pigs lunging onto the trailer from the loadout chute and losing traction. To accelerate quickly or to go up an incline, pigs will lunge with their hind limbs. When they lose traction while lunging, bedding and contamination is ejected backwards onto the chute. This was observed in almost every loadout of the study and is a likely source of transfer of contamination from the livestock trailer back into the loadout chute. Also, as more pigs are loaded, feces and urine accumulate on the loadout chute causing the wood shavings that are kicked from the trailer to stick to the boots of the loadout crew, allowing them to pick up contaminated particles and bring them back into the barn. An additional source of contamination frequently observed in the loadout chute was from pigs turning around from the livestock trailer and returning onto the chute throughout the study. Another factor observed during the study contributing to the contamination of the loadout chute and loadout alleyway were minor violations of the procedure. Throughout the duration of the study, the loadout crew had several minor and major violations noted in both the staged and conventional loading procedures. Some of these minor violations included a sorting panel crossing over a line of separation, possibly picking up contamination and bringing it back into the barn. Twice during the duration of the study, the driver exited the livestock trailer via the loadout chute when the loadout was complete, accounting for two of the major violations.

In one staged loading replicate, there was no contamination in the 5 center alleyway locations of the barn. However, in all other staged loading replicates, the procedure did not eliminate contamination in the center alleyway of the barn. The results of this study suggest that the staged loading procedure may reduce the likelihood of contamination, but it is not clear to what extent that likelihood is reduced and to what extent the level of contamination is clinically significant. Contamination may have resulted from pigs turning around in the loadout alleyway or chute and crossing the second line of separation to return to the barn alleyway. An exact count was not taken on number of pigs that turned around past the second line of separation for each treatment replicate. However, it is noted that at least one or more pigs turned around in each replicate either from the chute back into the loadout alleyway or from the loadout alleyway into the barn. Therefore, using appropriate gates or barriers may be warranted for staged loading to ensure that pigs cannot cross back over into the barn past the second line of separation. This may reduce the likelihood that the pigs would carry some contamination back into the barn from the livestock trailer. Other sources of contamination in the center alleyway of the barn were some minor violations, similar to those mentioned previously at the first line of separation. These minor violations, such as a sorting panel or boot crossing the second line of separation, were also observed.

Another challenge in the study was barn design. Some site designs were more complex and impacted the application of the staged loading procedure. Several of the study barns did not have a feasible buffer zone that was isolated from other pigs in the barn for the crew member designated to the loadout area to step into while pigs were being moved into the loadout area from the center alleyway of the barn. This did not interfere with the study, since a pen of pigs could be designated as the buffer zone therefore all measurements of contamination were taken in the center alleyway of the barn. However, this would defeat the purpose of using a staged loading procedure in practice. Ideally, a buffer zone would be adjacent to the loadout area, easy for Person 1 of the loadout crew to access and be isolated from other pigs in the barn. It would be beneficial for a buffer zone to be away from pigs in the barn so that cleaning and disinfection of the loadout area and buffer zone could be accomplished without contaminating the remaining pigs in the barn. Barn design must be considered when implementing a staged loading protocol.

There were several complications that took place during the study. Ideally, sites would have been randomly blocked by day of the week as initially planned. However, due to 3 replicates being discarded, last-minute changes in the production system loadout schedule, and lack of feasible buffer zones to accomplish a staged loading replicate, the replicates were unable to be blocked by day of the week. Day of the week may be important to account for when production systems wash livestock trailers and possibly if loadout crew members are more relaxed on rules or more likely to have violations the day after a weekend or the day before a weekend. More research may be needed to determine if day of the week has an impact on loading protocols.

Three loadout crews were used in this study. This did not impact the study results and was not statistically significant. All loadout crews were trained in the same procedures. The main objective of this study was to compare the level of contamination within the center alleyway of the barn between the two protocol groups.

The grid was a novel measurement approach first used in a study looking at the addition of a bench entry system to reduce the level of contamination.8 As in the previous study, the grid was used to quantify the level of contamination at the measurement points within the barn. However, if any fluorescent powder was observed in any 5 × 5 cm square, the square was counted as contaminated. The coverage within the square may have ranged from a small particle to complete coverage in the square.8 A higher resolution grid would result in a more precise measurement of contamination. High-quality photographs of the grid measurements may also be a viable option for future research to obtain more precise measurements of contamination and confirm contamination levels.

The sample size of 10 replicates/group was not based on a power calculation. Because this study was novel, reasonably good estimates of the mean differences and the standard deviation of the outcome measurements could not be made. Because the study assessing the bench entry system was conducted under entirely different conditions, the results were not considered useful for making such estimates for this study.8 Therefore, the sample size was selected arbitrarily.

The study was conducted in the summer, and even though temperature does not affect the fluorescent powder itself, it could affect the consistency of feces, urine, and organic material which would affect the outcome of the study. Since all the replicates were completed in the summer months, whether seasonality matters was beyond the scope of the study. The objective was to evaluate the staged loading protocol to reduce contamination levels, and not to take time of the year into account, although this may be important with wind and snow in the winter months.

The primary investigator was present for 18 of 20 replicates to measure and record for consistency. For 2 of the replicates, a secondary investigator took the place of the primary investigator. There is a possibility that there could be some inter-observer error, but this was believed to be nonsignificant due to the primary investigator being present a majority of the time.

Under the conditions of this study, staged loading reduced the amount of contamination conveyed from livestock trailers to the barn but did not eliminate it. This study highlights the importance of additional layers of biosecurity. Adding layers of biosecurity can reduce the frequency that contamination is conveyed from the livestock trailer to the barn, similar to the addition of a bench and shower upon farm entry.8 When contamination crosses the first line of separation, the second line of separation serves as a backup to reduce contamination transfer from the loadout chute to the center alleyway in the barn.

Implications

Under the conditions of this study:

- Staged loading reduced contamination transfer to the barns.

- Staged loading is an additional layer of biosecurity to reduce contamination.

- Evaluating barn design and employee training are warranted before implementing.

Acknowledgments

This study was funded by the Swine Health Information Center (Project No. 19-219 SHIC). The authors thank Iowa Select Farms for permitting access to their facilities and providing in-kind support from their veterinarians and marketing transportation supervisor. Special thanks to the members of the loadout crews for their time and efforts to learn and execute the staged loading procedures.

Conflict of interest

None reported.

Disclaimer

Scientific manuscripts published in the Journal of Swine Health and Production are peer reviewed. However, information on medications, feed, and management techniques may be specific to the research or commercial situation presented in the manuscript. It is the responsibility of the reader to use information responsibly and in accordance with the rules and regulations governing research or the practice of veterinary medicine in their country or region.

References

1. Holtkamp DJ, Kliebenstein JB, Neumann EJ, Zimmerman JJ, Rotto H, Yoder TK, Wang C, Yeske P, Mowrer C, Haley C. Assessment of the economic impact of porcine reproductive and respiratory syndrome virus on United States pork producers. J Swine Health Prod. 2013;21(2):72-84.

2. Alvarez J, Sarradell J, Morrison R, Perez A. Impact of porcine epidemic diarrhea on performance of growing pigs. PLoS ONE. 2015;10(3):e0120532. doi:10.1371/journal.pone.0120532

*3. Pavlovic L. Experiences managing wean-to-finish PEDV in a production system. In: Proceedings of the 49th AASV Annual Meeting. American Association of Swine Veterinarians; 2018:485-487.

4. Swine Disease Reporting System Report 18. 2019. Published August 6, 2019. Accessed August 2020. https://www.swinehealth.org/wp-content/uploads/2019/08/SHIC-109-DSDMR-August-8-5-19.pdf

5. Swine Disease Reporting System Report 19. 2019. Published September 3, 2019. Accessed August 2020. https://www.swinehealth.org/wp-content/uploads/2019/09/SHIC-109-DSDMR-September-9-3-19.pdf

6. Dee S, Deen J, Otake S, Pijoan C. An experimental model to evaluate the role of transport vehicles as a source of transmission of porcine reproductive and respiratory syndrome virus to susceptible pigs. Can J Vet Res. 2004;68:128-133.

7. Lowe J, Gauger P, Harmon K, Zhang J, Connor J, Yeske P, Loula T, Levis I, Dufresne L, Main R. Role of transportation in spread of porcine epidemic diarrhea virus infection, United States. Emerg Infec Dis. 2014;20:872-874.

8. Anderson AV, Fitzgerald C, Baker K, Stika R, Linhares D, Holtkamp DJ. Comparison of shower-in and shower-in plus bench entry protocols for prevention of environmental contamination due to personnel entry in a commercial swine facility. J Swine Health Prod. 2018:26(4):192-199.

9. Guo YP, Li Y, Wong PLH. Environment and body contamination: A comparison of two different removal methods in three types of personal protective clothing. Am J Infect Control. 2014;42(4):e39-e45. doi:10.1016/j.ajic.2013.12.021

10. Lai JYF, Guo YP, Or PPL, Li Y. Comparison of hand contamination rates and environmental contamination levels between two different glove removal methods and distances. Am J Infect Control. 2011;39(2):104-111.

11. Zamora JE, Murdoch J, Simchison B, Day AG. Contamination: A comparison of 2 personal protective systems. CMAJ. 2006;175(3):249-254.

12. Konicki T, Miller E. Use of a simulation intervention to examine differences in nursing students’ hand hygiene knowledge, beliefs, and behaviors. Nurse Educ Today. 2016;45:96-101.

* Non-refereed references.